Laina Hana Paipu PVC

Ninau I keia manawaHōʻike kikoʻī Huahana

| kumu hoʻohālike | FGE63 | FGE110 | FGE-250 | FGE315 | FGE630 | FGE800 |

| anawaena paipu | 20-63mm | 20-110mm | 75-250mm | 110-315mm | 315-630mm | 500-800mm |

| kumu hoʻohālike extruder | SJ65 | SJ75 | SJ90 | SJ90 | SJ120 | SJ120+SJ90 |

| mana kaʻa | 37kw | 55kw | 90kw | 160kw | 280kw | 280KW+160KW |

| kaha extrusion | 100kg/h | 150 kg | 220 kg | 400 kg | 700 kg | 1000 kg |

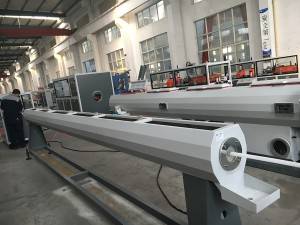

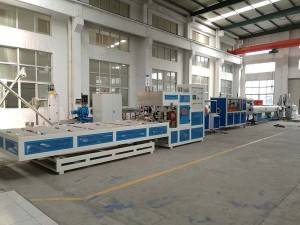

nui anawaena PVC paipu extrusion laina

Hoʻohana nui ʻia kēia laina no ka hana ʻana i nā paipu UPVC me nā diameters nui a me ka mānoanoa o ka pā paipu like ʻole i nā ʻano e like me ka plumbing mahiʻai a me ke kūkulu hale, cable layietc. ʻO ke anawaena kiʻekiʻe o ka paipu hiki ke 1200mm.

ʻO ke kaʻina hana o kēia laina e like me ka pupuhi

ʻO ka pauka PVC + mea hoʻohui --- hui ʻana---mea hānai---twin screw extruder---mould and calibrator---vacuum forming machine---spraying cooling machine---haul-off machine---cutting machine- --ka hoʻokuʻu ʻana a i ʻole ka mīkini bele paipu.

ʻO ka wili o ka extruder he hoʻolālā kiʻekiʻe, e hāʻawi i ka pale ikaika no ka plasticization PVC, a ʻo ka ʻōnaehana mana ʻo Siemens PLC e hana i ka hana maʻalahi. E hōʻoia ka ʻōnaehana degassing i ka maikaʻi o nā paipu PVC hope.

ʻO ke kino pahu o ka hoʻoheheʻe ʻana a me nā ʻāpana hoʻoluʻu e hoʻohana i ke kila kila 304 #, ʻo ka ʻōnaehana vacuum multi-sections e hōʻoia i ka nui a me ka hoʻomaha ʻana no nā paipu; Hoʻonui ka ʻōnaehana hoʻoluʻu kūikawā i ka maikaʻi o ka hoʻoilo; ʻOi aku ka naʻauao o ka mīkini i ka ʻōnaehana wela wai.

No ka nui o ka paipu, e hoʻohana ka mīkini huki i ʻelua anuhe, ʻekolu anuhe, ʻehā anuhe, ʻeono mau anuhe i hoʻolālā ʻia no nā koi like ʻole. Hoʻohana ʻo Pedrail clamping i ka ʻōnaehana hui mechanical a me ka pneumatic, ʻoi aku ka hilinaʻi i ka hana

Hoʻohana ʻia ka ʻōnaehana ʻoki ʻana i ka ʻoki lepo ʻole a i ʻole ke ʻano ʻoki honua; Aia kahi ʻōnaehana ʻohi lepo e hōʻoia i ka maʻemaʻe o ka hana.

ʻikepili ʻenehana

| kumu hoʻohālike | FGP160 | FGP250 | FGP315 | FGP630 | FGP800 |

| nui paipu | 50~160mm | 75~250mm | 110~315mm | 315~630mm | 500~800mm |

| extruder | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJZ92/188 | SJZ92/188 |

| mana kaʻa | 37kw | 55kw | 90kw | 110kw | 132kw |

| hoʻopuka | 250 kg | 350 kg | 550 kg | 600 kg | 700 kg |

Paipai ʻia nā huahana

ʻOi aku +-

Laina extrusion hose wili PVC

Hoʻohana ʻia kēia laina no ka hana ʻana i nā hoses māla i hoʻoikaika ʻia i ka fiber PVC me ke anawaena mai 8mm a 50mm. Hana ʻia ka paia o ka hose me ka mea PVC. Aia ma waenakonu o ka hose he fiber. E like me ka noi, hiki iā ia ke hana i nā paipu wili me nā kala ʻokoʻa, ʻekolu papa i hoʻopaʻa ʻia i nā paipu, ʻelima papa i hoʻopaʻa ʻia.

Hoʻohana ka extruder i hoʻokahi wili me ka plasticization maikaʻi loa; ʻO ka mīkini haul off he 2 mau maiuu me ka wikiwiki e alakaʻi ʻia e ABB inverter; Me ka pono, hiki i ka papa fiber ke ʻano crochet a me ke ʻano wili.

Loaʻa ka maikaʻi o ka hose braided o ka extrusion resistance, corrosion resistance, static electricity resistance, anti-high pressure a me ka holo maikaʻi. He kūpono ia no ka lawe ʻana i ke kaomi kiʻekiʻe a i ʻole ke kinoea hoʻopau ʻana a me ka wai, ka hoʻoheheʻe kaumaha a me ka hāʻawi ʻana i ka sludge wai. Hoʻohana nui ʻia i ka māla a me ka irrigation lawn.

E aʻo hou aku -

Mīkini Hoʻokahi Screw Plastic Extruder

Hoʻohana nui ʻia no ka extruding thermoplastics, e like me PE, PP, PS, PVC, ABS, PC, PET a me nā mea plastik ʻē aʻe. Me nā mea pono i lalo (me ka moud), hiki iā ia ke hana i nā ʻano mea like ʻole, no ka laʻana, nā paipu plastik, profiles, panel, sheet, plastic granules a pēlā aku.

Loaʻa i ka SJ series single screw extruder ka maikaʻi o ka puka kiʻekiʻe, ka plasticization maikaʻi loa, ka hoʻohana haʻahaʻa haʻahaʻa, ka holo paʻa. ʻO ka pahu pahu o ka extruder screw hoʻokahi e hoʻohana i ka pahu pahu kiʻekiʻe kiʻekiʻe, nona nā hiʻohiʻona o ka haʻahaʻa haʻahaʻa, ke kiʻekiʻe o ka lawe ʻana, ke ola lawelawe lōʻihi; ʻO ka sccrew a me ka pahu e hoʻohana i ka mea 38CrMoAlA, me ka mālama nitriding; hoʻohana ke kaʻa i ka mīkini maʻamau Siemens; hoʻohana ka mea hoʻohuli i ka ABB inverter; Hoʻohana ka mea hoʻoponopono wela iā Omron/RKC; Hoʻohana nā uila haʻahaʻa haʻahaʻa i nā uila Schneider.

E aʻo hou aku -

Mīkini Crusher Plastic

Hoʻomaʻemaʻe ʻia ka mea paʻi me ka i, ported special too-steel, hiki ke hoʻololi ʻia ka ʻae ʻana ma waena o nā mea paʻi pahi, ke lilo ʻo ia i blunt ma ka hoʻohana ʻana, hiki ke hoʻokuʻu pinepine ʻia, ua paʻa.

• E hoʻohana i nā wili kila kiʻekiʻe no ka hoʻopaʻa ʻana i ka lau pahi a me ka noho pahi, me ka ikaika e hiki ai.

• Hoʻopili ʻia nā paia a pau o ke keʻena paʻi e ka leo-pono, no laila me ka leo haʻahaʻa eatra

• He 'ano ho'emi i ho'olālā 'ia, ka bunker, kino nui, Sieve hiki ke ho'oku'u 'ia no ka ho'oma'ema'e ma'alahi, ke kaumaha me ka mea pale lepo.

E aʻo hou aku -

Laina holoi holoi a hoʻomaloʻo ʻana i ka hue pipi

Hoʻololi kēia ʻōmole ʻōpala Pet, holoi a hoʻomaloʻo i nā ʻōmole holoholona ʻōpala i loko o nā flakes PET maʻemaʻe. A hiki ke hana hou a hoʻohana hou ʻia nā flakes me ka waiwai kālepa kiʻekiʻe. ʻO ka mana hana o kā mākou PET Bottle crushing and washing line hiki ke 300kg / h a 3000kg / h. ʻO ke kumu nui o kēia hana hou ʻana i nā holoholona, ʻo ia ka loaʻa ʻana o nā flakes maʻemaʻe mai nā ʻōmole lepo a hui pū ʻia paha i ka wā e hana ai i ka laina holoi holoʻokoʻa. A e kiʻi pū i nā pāpale PP/PE maʻemaʻe, nā lepili mai nā hue, etc.

E aʻo hou aku -

3 papa PERT (glue, UVH) laina hana paipu

Hoʻohana nui ia no ka hana ʻana i nā paipu PP-R, PE me ke anawaena mai 16mm ~ 160mm, nā paipu PE-RT me ke anawaena mai 16 ~ 32mm. Hoʻolako ʻia me nā mea pono o lalo, hiki iā ia ke hana i nā paipu mufti-layer PP-R, nā paipu fiber aniani PP-R, PE-RT a me nā paipu EVOH. Me nā makahiki o ka ʻike no ka extrusion paipu plastik, ua hoʻomohala pū mākou i ka laina kiʻekiʻe PP-R/PE pipe extrusion line, a ʻo ka wikiwiki hana kiʻekiʻe hiki ke 35m/min (kumu ma nā paipu 20mm).

E aʻo hou aku -

ʻO ka mīkini wili paipu ʻakomi

1.this moʻo hiki ke hana Φ16-1000mm kekahi paipu flaring

2.me ka hoʻouna 'akomi tube.flip tube.flaring hana

3.with heating.cooling.timing.automatic.manual hana

4.ka hoʻolālā modular o nā mea

5. liʻiliʻi liʻiliʻi

6. ka hoʻohana 'ana i ka vacuum adsorption.flaring a maopopo profile.size assurance

7. mana (hoʻohālikelike ʻia me nā huahana like. 50% mālama mana)

8. hiki ke hoʻopiliʻia e like me nā koi o ka mea hoʻohana i nā kiko'ī kūikawā

E aʻo hou aku

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur