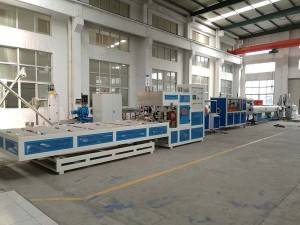

Plastic recycling pelletizing line

Botsa JoaleHDPE pipe extrusion line

Mohala ona o sebelisoa haholo-holo ho etsa li-granules ho tloha litšila tsa polasetiki, tse kang PP, PE, PS, ABS, PA flakes, PP / PE lifilimi tse setseng. Bakeng sa lisebelisoa tse fapaneng, mohala ona oa pelletizing o ka etsoa e le extrusion ea sethala se le seng le sethala sa habeli. The pelletizing system e ka ba "die-face pelletizing" le "noodle-cut pelletizing".

Mohala ona oa polasetiki oa granulating o amohela taolo ea mocheso o ikemetseng le ts'ebetso e tsitsitseng. The bi-metal screw le barrel lia fumaneha le alloy e khethehileng e e fang matla le bophelo bo bolelele ba ts'ebeletso. E na le moruo haholoanyane mohloling oa matla a motlakase le metsi. Tlhahiso e kholo, bophelo bo bolelele ba tšebeletso le lerata le tlaase

Tekheniki parameter

| Mohlala | Extruder | Screw Diameter | L/D | Bokhoni (kg/hora) |

| SJ-85 | SJ85/33 | 85 limilimithara | 33 | 100-150kg / hora |

| SJ-100 | SJ100/33 | 100mm | 33 | 200kg / hora |

| SJ-120 | SJ120/33 | 120 limilimithara | 33 | 300kg / hora |

| SJ-130 | SJ130/30 | 130 limilimithara | 33 | 450kg / hora |

| SJ-160 | SJ160/30 | 160 limilimithara | 33 | 600kg / hora |

| SJ-180 | SJ180/30 | 180 limilimithara | 33 | 750-800kg / hora |

Lihlahisoa tse khothalelitsoeng

Tse ling +-

WPC profil extrusion line

Mohala ona o sebelisoa haholo ho hlahisa lifaele tse fapaneng tsa WPC, joalo ka profil ea WPC, phanele ea WPC, boto ea WPC.

Mokhoa oa ho phalla oa mola onakePP/PE/PVC + phofo ea lehong + addititive — mixing—material feeder—twin screw extruder— hlobo le calibrator—tafole ea ho etsa vacuum—mochini oa ho hula—mochini o sehang—rack ea ho ntša metsi.

Mohala ona oa extrusion oa WPC profil o sebelisa conic twin screw extruder, e nang le sistimi ea degassing ho netefatsa hore polasetiki e ntle haholo. Hlobo le calibrator li nka thepa e ka aparoang; mochini oa ho hula le mochini o sehang o ka etsoa e le yuniti e felletseng kapa mochini o arohaneng.

Ithute haholoanyane -

Mochini o le Mong oa ho Etsa Lipeipi tsa Lebota le le Leng

Mohala ona o sebelisoa haholo ho hlahisa liphaephe tse fapaneng tsa lebota le le leng le bophara ba 6mm ~ 200mm. E ka sebetsa ho PVC, PP, PE, PVC, PA, thepa ea EVA. Mohala o felletseng o kenyelletsa: loader, Single screw extruder, die, mochini o entsoeng ka masenke, coiler. Bakeng sa thepa ea phofo ea PVC, re tla fana ka maikutlo a conic twin screw extruder bakeng sa tlhahiso.

Mohala ona o sebelisa extruder e sebetsang hantle ea matla e le 'ngoe; mochini oa ho etsa o na le li-gear run modules le li-templates ho hlokomela ho pholisa ho hoholo ha lihlahisoa, e leng se tiisang hore ho bōptjoa ka lebelo le phahameng, esita le corrugation, lerako le boreleli la ka hare le ka ntle. Li-electrics tsa mantlha tsa mohala ona li amohela mofuta o tummeng oa lefats'e, joalo ka Siemens, ABB, Omron/RKC, Schneider joalo-joalo.

Ithute haholoanyane -

Mochini o iketselitseng oa phala

1.letoto lena le ka sebetswa Φ16-1000mm leha e le efe phaephe flaring

2.ka mokhoa o itekanetseng oa ho fana ka tube.flip tube.flaring mosebetsi

3.ka ho futhumatsa.cooling.timing.automatic.manual function

4. moralo oa modular oa likarolo

5.boholo bo nyane.lerata le tlase

6.tshebediso ya vacuum adsorption.flaring profile e hlakileng.tiisetso ea boholo

7.matla (ha a bapisoa le lihlahisoa tse tšoanang.ho boloka matla 50%)

8.e ka etsoa ho latela litlhoko tsa mosebelisi litlhaloso tse khethehileng

Ithute haholoanyane -

Conical twin screw extruder

SJSZ series conical twin screw extruder e haholo-holo e entsoe ka barrel screw, gear transmission system, quantitative feeding, vacuum exhaust, futhumatsang, pholileng le likarolo tsa motlakase tsa taolo Etc. Conical twin screw extruder e loketse ho hlahisa lihlahisoa tsa PVC ho tloha phofo e tsoakiloeng.

Ke thepa e khethehileng bakeng sa PVC phofo kapa WPC phofo extrusion. E na le melemo ea ho kopanya hantle, tlhahiso e kholo, ho matha ho tsitsitseng, bophelo bo bolelele ba tšebeletso. Ka thepa e fapaneng ea hlobo le e tlase, e ka hlahisa liphaephe tsa PVC, siling ea PVC, profiles ea lifensetere tsa PVC, lakane ea PVC, decking ea WPC, li-granules tsa PVC joalo-joalo.

Li-screw tse ngata tse fapaneng, li-screw extruder tse peli li na le li-screw tse peli, sigle screw extruder e na le sekoti se le seng feela, Li sebelisetsoa lisebelisoa tse fapaneng, li-scruder tse peli tse atisang ho sebelisoa bakeng sa PVC e thata, screw e le 'ngoe e sebelisetsoang PP/PE. Double screw extruder e ka hlahisa liphaephe tsa PVC, profiles le granules tsa PVC. 'Me extruder e le' ngoe e ka hlahisa liphaephe tsa PP / PE le granules.

Ithute haholoanyane -

Mohala oa ho hlatsoa le ho omisa botlolo ea phoofolo ea lapeng

Mohala ona oa ho sila, oa ho hlatsoa le ho omisa o fetola libotlolo tsa litšila hore e be li-flakes tse hloekileng tsa PET. 'Me li-flakes li ka sebetsoa le ho sebelisoa hape ka boleng bo phahameng ba khoebo. Bokhoni ba tlhahiso ea PET Bottle ea rona ea ho pshatla le ho hlatsoa mohala e ka ba 300kg/h ho isa ho 3000kg/h. Morero o ka sehloohong oa phepelo ena ea liphoofolo tse ruuoang lapeng ke ho fumana li-flakes tse hloekileng ho tsoa libotlolong tse silafetseng tsa motsoako kapa selae sa libotlolo nakong ea ho sebetsana le mohala oohle oa ho hlatsoa. Hape u fumane likatiba tse hloekileng tsa PP/PE, mangolo a tsoang libotlolong joalo-joalo.

Ithute haholoanyane -

Mochine oa liphaephe oa PPR

E sebelisoa haholo bakeng sa ho hlahisa PP-R, liphaephe tsa PE tse bophara ba 16mm ~ 160mm, liphaephe tsa PE-RT tse bophara ba 16 ~ 32mm. E na le lisebelisoa tse nepahetseng tse tlase, e ka boela ea hlahisa liphaephe tsa PP-R tsa mufti-layer, lipeipi tsa fiber tsa khalase tsa PP-R, lipeipi tsa PE-RT le EVOH. Ka phihlelo ea lilemo tse ngata bakeng sa extrusion ea liphaephe tsa polasetiki, re boetse re ntlafalitse lebelo le phahameng la PP-R / PE pipe extrusion line, 'me lebelo la tlhahiso ea max e ka ba 35m / min (e thehiloeng holim'a liphaephe tsa 20mm).

Ithute haholoanyane

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur