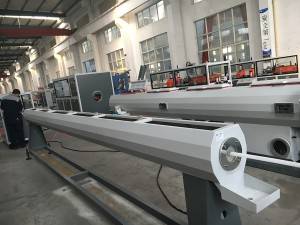

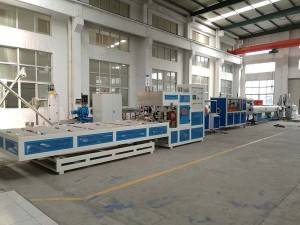

PVC Pipe Production Line

Botsa JoaleTlhaloso e qaqileng ea Sehlahisoa

| mohlala | FGE63 | FGE110 | FGE-250 | FGE315 | FGE630 | FGE800 |

| bophara ba phala | 20-63 limilimithara | 20-110 limilimithara | 75-250 limilimithara | 110-315 limilimithara | 315-630 limilimithara | 500-800 limilimithara |

| mohlala oa extruder | SJ65 | SJ75 | SJ90 | SJ90 | SJ120 | SJ120+SJ90 |

| matla a motlakase | 37kw | 55kw | 90kw | 160kw | 280kw | 280KW+160KW |

| bokhoni ba extrusion | 100kg/h | 150kg | 220kg | 400kg | 700kg | 1000kg |

bophara bo boholo PVC phala extrusion line

Mohala ona o sebelisoa haholo bakeng sa ho hlahisa lipeipi tsa UPVC tse nang le bophara bo boholo le botenya bo fapaneng ba lebota la liphaephe likarolong tse kang tsa temo le lipeipi tsa kaho, cable layietc. Bophara bo boholo ba phala e ka ba 1200mm.

Tsela ea ho phalla ha mohala ona e le ho otla

PVC powder + additive --- kopanya---material feeder---twin screw extruder---mold le calibrator---vacuum forming machine---spraying cooling machine---huul-off machine---mochine o sehang- -- rack e ntšang kapa mochini o betsang lipeipi.

The screw of extruder e na le moralo o tsoetseng pele, o fanang ka tšireletso e matla bakeng sa polasetiki ea PVC, mme sistimi ea taolo ea Siemens PLC e etsa ts'ebetso e bonolo haholoanyane. Mokhoa oa ho tlosa metsi o tla netefatsa boleng ba lipeipi tsa ho qetela tsa PVC.

Setsi sa tanka sa vacuum calibration le pholileng se nka tšepe e sa hloekang ea 304#, sistimi e nang le likarolo tse ngata e netefatsa hore boholo bo tsitsitse le ho phophola ha liphaephe; Sistimi e khethehileng ea ho futhumatsa e ntlafatsa ts'ebetso ea pholiso; Sistimi ea ho laola mocheso oa metsi ka boiketsetso e etsa hore mochini o be bohlale haholoanyane.

Bakeng sa boholo bo fapaneng ba liphaephe, mochine oa ho hula o tla amohela popane tse peli, popane e meraro, popane e mene, popane e tšeletseng e etselitsoe litlhoko tse fapaneng. Pedrail clamping e sebelisa sistimi e kopanyang ea mochini le ea pneumatic, e ts'epahalang haholoanyane ts'ebetsong

Sistimi ea ho itšeha e amohela sehahi se se nang lerōle kapa mokhoa oa ho seha polanete; Ho na le sistimi ea ho bokella lerole e netefatsang tikoloho e hloekileng ea ho sebetsa.

Lintlha tsa tekheniki

| mohlala | FGP160 | FGP250 | FGP315 | FGP630 | FGP800 |

| boholo ba phala | 50-160 limilimithara | 75-250 limilimithara | 110-315 limilimithara | 315-630 limilimithara | 500-800 limilimithara |

| extruder | SJZ65/132 | SJZ80/156 | SJZ92/188 | SJZ92/188 | SJZ92/188 |

| matla a motlakase | 37kw | 55kw | 90kw | 110kw | 132kw |

| tlhahiso | 250kg | 350kg | 550kg | 600kg | 700kg |

Lihlahisoa tse khothalelitsoeng

Tse ling +-

PVC braided hose extrusion line

Mohala ona o sebelisetsoa ho hlahisa liphaephe tsa PVC tse matlafalitsoeng tsa serapa ka bophara ho tloha ho 8mm ho isa ho 50mm. Lerako la hose le entsoe ka thepa ea PVC. Bohareng ba hose, ho na le fiber. Ho ea ka kopo, e ka etsa hose e lohiloeng ka mebala e fapaneng, li-hoses tse tharo tse lohiloeng, tse hlano tsa lera tse lohiloeng.

The extruder e amohela sekoti se le seng ka polasetiki e ntle haholo; mochini oa hul off o na le manala a 2 ka lebelo le laoloang ke inverter ea ABB; Ka mokhoa o nepahetseng, lesela la fiber e ka ba mofuta oa crochet le mofuta o lohiloeng.

Hose e lohiloeng e na le monyetla oa ho hanyetsa extrusion, ho hanyetsa kutu, ho hanyetsa motlakase o tsitsitseng, khatello e matla le ho sebetsa hantle. E loketse ho fetisa khatello e phahameng kapa khase e tukang le mokelikeli, ho hula ka matla le ho fana ka seretse sa metsi. E sebelisoa haholo-holo serapeng le ho nosetsa mohloa.

Ithute haholoanyane -

Mochini o le Mong oa Screw Plastic Extruder

E sebelisoa haholo bakeng sa extruding thermoplastics, joalo ka PE, PP, PS, PVC, ABS, PC, PET le lisebelisoa tse ling tsa polasetiki. Ka lisebelisoa tse sebetsang tse tlase (ho kenyeletsoa moud), e ka hlahisa mefuta e fapaneng ea lihlahisoa tsa polasetiki, mohlala, liphaephe tsa polasetiki, profil, phanele, lakane, li-granules tsa polasetiki joalo-joalo.

SJ Series single screw extruder e na le melemo ea tlhahiso e phahameng, polasetiki e ntle haholo, tšebeliso e tlase ea matla, ts'ebetso e tsitsitseng. Lebokose la gear la "screw extruder" le amohela lebokose la gear le phahameng la torque, le nang le likarolo tsa lerata le tlase, matla a ho jara a phahameng, bophelo bo bolelele ba ts'ebeletso; screw le barrel li amohela lisebelisoa tsa 38CrMoAlA, ka kalafo ea nitriding; enjene e amohela enjene e tloaelehileng ea Siemens; inverter amohela ABB inverter; molaoli oa mocheso o amohela Omron/RKC; Li-electric tsa khatello e tlase li sebelisa motlakase oa Schneider.

Ithute haholoanyane -

Mochini oa ho Crusher oa polasetiki

.Sesebelisoa sa thipa se hloekisoa ka i, ported special too-steel, the clearance between thipa tools are adjustable, ha e ba lerootho ha e sebelisoa, e ka theoloa khafetsa, e ea tšoarella.

• Sebelisa likurufu tsa tšepe tse matla haholo ho tiisa lekhasi la thipa le setulo sa thipa, tse nang le matla a ho jara.

• Mabota ohle a kamore e pshatlehang a ts'oaroa ka hore a se ke a utloa molumo, kahoo ho ba le lerata le tlase la eatra

• Mofuta oa theolelo o etselitsoeng, bunker, 'mele o ka sehloohong,Sieve e ka theoloa hore e hloekisoe habonolo, e boima ka sesebelisoa sa ts'ireletso ea lerōle.

Ithute haholoanyane -

Mohala oa ho hlatsoa le ho omisa botlolo ea phoofolo ea lapeng

Mohala ona oa ho sila, oa ho hlatsoa le ho omisa o fetola libotlolo tsa litšila hore e be li-flakes tse hloekileng tsa PET. 'Me li-flakes li ka sebetsoa le ho sebelisoa hape ka boleng bo phahameng ba khoebo. Bokhoni ba tlhahiso ea PET Bottle ea rona ea ho pshatla le ho hlatsoa mohala e ka ba 300kg/h ho isa ho 3000kg/h. Morero o ka sehloohong oa phepelo ena ea liphoofolo tse ruuoang lapeng ke ho fumana li-flakes tse hloekileng ho tsoa libotlolong tse silafetseng tsa motsoako kapa selae sa libotlolo nakong ea ho sebetsana le mohala oohle oa ho hlatsoa. Hape u fumane likatiba tse hloekileng tsa PP/PE, mangolo a tsoang libotlolong joalo-joalo.

Ithute haholoanyane -

3 layer PERT (sekhomaretsi, UVH) mohala oa tlhahiso ea liphaephe

E sebelisoa haholo bakeng sa ho hlahisa PP-R, liphaephe tsa PE tse bophara ba 16mm ~ 160mm, liphaephe tsa PE-RT tse bophara ba 16 ~ 32mm. E na le lisebelisoa tse nepahetseng tse tlase, e ka boela ea hlahisa liphaephe tsa PP-R tsa mufti-layer, lipeipi tsa fiber tsa khalase tsa PP-R, lipeipi tsa PE-RT le EVOH. Ka phihlelo ea lilemo tse ngata bakeng sa extrusion ea liphaephe tsa polasetiki, re boetse re ntlafalitse lebelo le phahameng la PP-R / PE pipe extrusion line, 'me lebelo la tlhahiso ea max e ka ba 35m / min (e thehiloeng holim'a liphaephe tsa 20mm).

Ithute haholoanyane -

Mochini o iketselitseng oa phala

1.letoto lena le ka sebetswa Φ16-1000mm leha e le efe phaephe flaring

2.ka mokhoa o itekanetseng oa ho fana ka tube.flip tube.flaring mosebetsi

3.ka ho futhumatsa.cooling.timing.automatic.manual function

4. moralo oa modular oa likarolo

5.boholo bo nyane.lerata le tlase

6.tshebediso ya vacuum adsorption.flaring profile e hlakileng.tiisetso ea boholo

7.matla (ha a bapisoa le lihlahisoa tse tšoanang.ho boloka matla 50%)

8.e ka etsoa ho latela litlhoko tsa mosebelisi litlhaloso tse khethehileng

Ithute haholoanyane

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur