18 Years Factory Pet Bottle Blow Molding Machine - PET Bottle Blowing machine – FAYGO

Inquiry Now18 Years Factory Pet Bottle Blow Molding Machine - PET Bottle Blowing machine – FAYGO Detail:

FG series PET Bottle Blowing machine

FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still stays around 1200BPH, while international max single-mold speed has reached 1800BPH. High-speed linear blowing machines rely on imports. In view of this situation, Faygo Union Machinery developed China first high speed linear blowing machine: FG series bottle blowing machine, whose single-mold speed can reach 1800~2000BPH. FG series bottle blowing machine include three model right now: FG4 (4-cavity),FG6(6-cavity),FG8 (8-cavity), and the max speed could be 13000BPH. It is developed totally independently, has our own intellectual property rights, and has obtained more than 8 national patents.

This machine is equipped with automatic perform loading and bottle unloading system. It is applicable for all shapes of drinking water bottles, carbonated bottles and hot filling bottles. FG4 is composed of three modules: prefrom elevator, perform unscrambler and host machine.

FG series bottle blowing machine is a completely new generation of linear blowing machine, distinguished by its high speed, low power and low compressed air consumption, featured by the excellent structure design, small space occupation, less noise and high stability, meanwhile conforms to national beverage sanitary standards. This machine symbolizes the highest level of national linear blowing machines. It is the ideal bottle making equipment for medium and large enterprises.

FG Series Product Advantages

1. Servo driving and cam linking blowing section:

The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement, equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

2. Small performs distance heating system

Heater distance in the heating oven is reduced to 38mm, compared with the conventional heating oven it saves more than 30% electricity consumption.

Equipped with the air cycling system and redundant heat discharge system, it ensures the constant temperature of the heating zone.

3. Efficient and soft perform inlet system

By rotary and soft preform inlet system, the speed of prefom feeding is ensured meanwhile, the preform neck is well protected.

4. Modularized design conception

Adopting modularized design concept, to make it convenient and cost-saving for the maintenance and changing spare parts.

Technical parameter

|

Model |

FG4 |

FG6 |

FG8 |

Remark |

||

| Mold number(piece) |

4 |

6 |

8 |

|||

| Capacity(BPH) |

6500~8000 |

9000~10000 |

12000~13000 |

|||

|

Bottle specification |

Max volume(mL) |

2000 |

2000 |

750 |

||

| Max height(mm) |

328 |

328 |

328 |

|||

| Round bottle max diameter(mm) |

105 |

105 |

105 |

|||

| Square bottle max diagonal(mm) |

115 |

115 |

115 |

|||

|

Preform specification |

Suitable inner bottle neck(mm) |

20–25 |

20–25 |

20–25 |

||

| Max preform length(mm) |

150 |

150 |

150 |

|||

|

Electricity |

Total installation power(kW) |

51 |

51 |

97 |

||

| Heating oven real power(kW) |

25 |

30 |

45 |

|||

| Voltage/frequency(V/Hz) |

380(50Hz) |

380(50Hz) |

380(50Hz) |

|||

|

Compressed air |

Pressure(bar) |

30 |

30 |

30 |

||

|

Cooling water |

Mold water | Pressure(bar) |

4-6 |

4-6 |

4-6 |

Water chiller (5HP) |

| Temperature regulation range(°C) |

6–13 |

6–13 |

6–13 |

|||

| Oven water | Pressure(bar) |

4-6 |

4-6 |

4-6 |

Water chiller (5HP) |

|

| Temperature regulation range(°C) |

6-13 |

6-13 |

6-13 |

|||

|

Machine specification |

Machine dimension(m)(L*W*H) |

3.3X1X2.3 |

4.3X1X2.3 |

4.8X1X2.3 |

||

| Machine weight(Kg) |

3200 |

3800 |

4500 |

|||

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our organization has strived to establish a highly efficient and stable employees team and explored an effective high-quality command method for 18 Years Factory Pet Bottle Blow Molding Machine - PET Bottle Blowing machine – FAYGO , The product will supply to all over the world, such as: Liberia, Zambia, Bangladesh, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

Products Recommended

More +-

Trending Products Pet Preform Injection Molding Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

Short Lead Time for Pipe Belling Machine - PVC profile extrusion line – FAYGO

HDPE pipe extrusion line This line is widely used for producing various PVC profiles, such as PVC window&door profile, PVC ceiling panel, PVC trunking. The process flow of this line is PVC...Learn more -

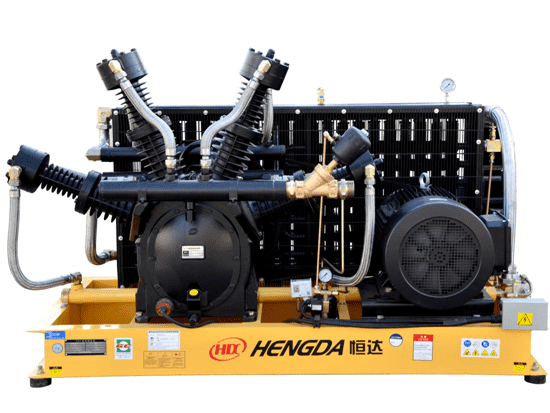

8 Year Exporter 3 Phase Screw Compressor - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more -

Factory directly Silent Portable Air Compressor - Booster compressor – FAYGO

Learn more -

Big Discount Erw Pipe Production Line - PP pipe production line – FAYGO

PP-R/PE-RT pipe extrusion line It is main used for producing PP-R, PE pipes with diameter from 16mm~160mm, PE-RT pipes with diameter from 16~32mm. Equipped with proper downstream equipment, it...Learn more -

Factory best selling Quiet Small Air Compressor - SCREW COMPRESSSOR – FAYGO

Introduction Full-automatically load and unload control the input air full automatically. Compressor will start automatically when there is no pressure, and will stop working when the pressure...Learn more