Best quality Plastic Compounding Pelletizing Machine - Single Screw Plastic Extruder Machine – FAYGO

Inquiry NowBest quality Plastic Compounding Pelletizing Machine - Single Screw Plastic Extruder Machine – FAYGO Detail:

HDPE pipe extrusion line

It is mainly used for extruding thermoplastics, such as PE, PP, PS, PVC, ABS, PC, PET and other plastic material. With relevant downstream equipment (including moud), it can produce various kinds of plastic products, for example plastic pipes, profiles, panel, sheet, plastic granules and so on.

SJ series single screw extruder has advantages of high output, excellent plasticization, low energy consumption, stable running. The gearbox of single screw extruder adopt high torque gear box, which has features of low noisy, high carrying capacity, long service life; the sccrew and barrel adopt 38CrMoAlA material, with nitriding treatment; the motor adopt Siemens standard motor; inverter adopt ABB inverter; temperature controller adopt Omron/RKC; Low pressure electrics adopt Schneider electrics.

By different requirement, SJ series single screw extruder could be designed as PLC touch screen control type extruder and panel control type extruder. The screw could adopt high speed screw to achieve more output.Advantage:

1. world famous brands major parts: SIEMENS motor, ABB/FUJI/LG/OMRON inverters, SIEMENS/Schneider contactors, OMRON/RKC temperature controllers, DELTA/SIEMENS PLC system

2. Experience engineers all with passports ready for customers services.

3. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.

Technical parameter

|

Model |

SJ25 |

SJ45 |

SJ65 |

SJ75 |

SJ90 |

SJ120 | SJ150 |

|

Screw Dia.(mm) |

25 |

45 |

65 |

75 |

90 |

120 | 150 |

|

L/D |

25 |

25-33 |

30-33 |

30-33 |

30-33 |

30-33 | 30-33 |

|

Main Motor(KW) |

1.5 |

15 |

30/37 |

55/75 |

90/110 |

110/132 | 132/160 |

|

Output (KG/H) |

2 |

35-40 |

80-100 |

160-220 |

250-320 |

350-380 | 450-550 |

|

Centre height |

1050 |

1050 |

1050 |

1050 |

1100 |

1100 | 1100 |

|

Net Weight(KG) |

200 |

600 |

1200 |

2500 |

3000 |

4500 | 6200 |

|

L*W*H(m) |

1.2X0.4X1.2 |

2.5X1.1X1.5 |

2.8X1.2X2.3 |

3.5X1.4X2.3 |

3.5X1.5X2.5 |

4.8X1.6X2.6 | 6X1.6X2.8 |

Video

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Best quality Plastic Compounding Pelletizing Machine - Single Screw Plastic Extruder Machine – FAYGO , The product will supply to all over the world, such as: Spain, Uganda, Morocco, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.

Products Recommended

More +-

Super Purchasing for Fruit Juice Packing Machine - PET bottle juice filling machine – FAYGO

Product introduction This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce PET bottled juice and other non-gas beverage. The CGF Wash-filling-capping 3-in-1unit:Bevera...Learn more -

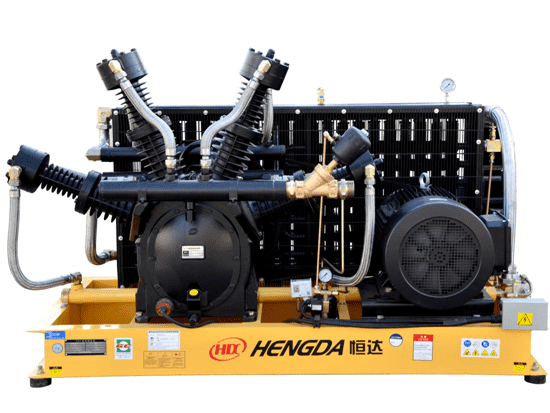

Factory wholesale Air Venturi Nomad Ii - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more -

factory customized 77p Compressor - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more -

Fast delivery Recycling Ldpe Film - Plastic Crusher Machine – FAYGO

Detailed Product Description Voltage: 380V, 3 Phase, 50Hz Weight: 1200kg Rotating Blades: 18pcs Company: Faygo Power(W): 18.5kw Dimension(L*W*H): 1500*1800*2000 Rotating Speed: 500rpm/m Model ...Learn more -

Reliable Supplier Diesel Screw Compressor For Sale - Booster compressor – FAYGO

Learn more -

China New Product Plastic Extrusion Machine Extruder - 12-575mm6.5mm thick PE pipe production line – FAYGO

PP-R/PE-RT pipe extrusion line It is main used for producing PP-R, PE pipes with diameter from 16mm~160mm, PE-RT pipes with diameter from 16~32mm. Equipped with proper downstream equipment, it can ...Learn more