Factory selling Mini Plastic Extrusion Machine - Pet bottle crushing washing and drying line – FAYGO

Inquiry NowFactory selling Mini Plastic Extrusion Machine - Pet bottle crushing washing and drying line – FAYGO Detail:

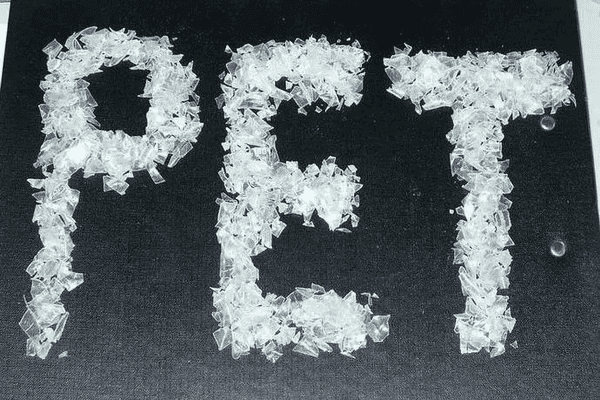

This Pet bottle crushing, washing and drying line transforms waste pet bottles into clean PET flakes. And the flakes can be further processed and re-utilized with high commercial value. The production capacity of our PET Bottle crushing and washing line can be 300kg/h to 3000kg/h. The main purpose of this pet recycling is to get the clean flakes from the dirty even mixture bottles or bottles slice during dealing with the whole washing line. And also get clean PP/PE caps, labels from the bottles etc.

The PET bottle recycling line is consist of the following machines: de-baler, trammel, label remover ,manual sorting table, metal detector, crusher, pre-washer, hot washer, friction washer, float washing tank, dewaterer, drier, zigzag separator, storage hopper and electric control cabinet.

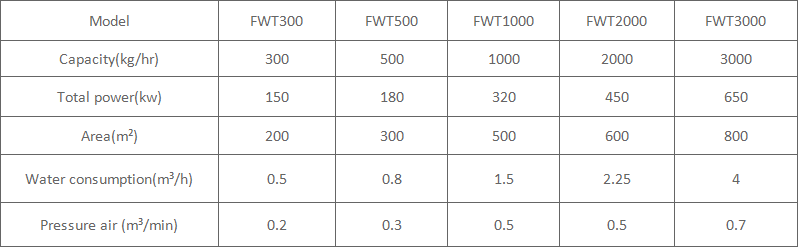

Technical data:

2.PP, PE Crushing, washing and drying line

This PP, PE Crushing, washing and drying line is mainly used to clean the waste plastics, such as PE HDPE LDPE LLDPE PP BOPP Film, bags, bottles, Jerry cans, bucket, basket etc. The waste dirty material will go through crushing, washing, drying, and collecting process, and turn to be clean flakes for pelletizing.

With high efficient crushing,washing and drying, the client can make clean plastic scraps from waste plastics with lowest cost.

The PP, PE recycling line mainly include crusher or shredder machine, friction washer machine, float washing tank, High speed friction washer machine, dewatering machine, hot air dryer system, storage silo etc.

The clean material machine from this washing line can be used to making plastic granules. Our company also supply plastic granulating machine for next process

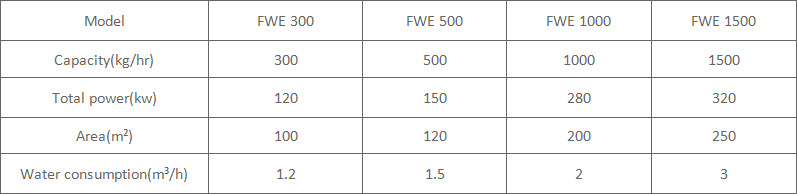

Technical data:

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for Factory selling Mini Plastic Extrusion Machine - Pet bottle crushing washing and drying line – FAYGO , The product will supply to all over the world, such as: Madrid, Accra, Austria, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

Products Recommended

More +-

Low price for Bottle Filling Machine Price - PET bottle juice filling machine – FAYGO

Product introduction This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce PET bottled juice and other non-gas beverage. The CGF Wash-filling-capping 3-in-1unit:Bevera...Learn more -

2021 China New Design 7-13 Bar Direct Driven Screw Air Compressor - Booster compressor – FAYGO

Learn more -

Special Design for Manual Liquid Filler - PET bottle juice filling machine – FAYGO

Product introduction This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce PET bottled juice and other non-gas beverage. The CGF Wash-filling-capping 3-in-1unit:Bevera...Learn more -

OEM/ODM Supplier Venturi Nomad 2 - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more -

Hot-selling Plastic Bottle Manufacturing Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

Leading Manufacturer for Plastic Water Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more