High Quality Manual Filling Machine For Creams - PET bottle juice filling machine – FAYGO

Inquiry NowHigh Quality Manual Filling Machine For Creams - PET bottle juice filling machine – FAYGO Detail:

Product introduction

This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce PET bottled juice and other non-gas beverage.

The CGF Wash-filling-capping 3-in-1unit:Beverage Machinery can finish all the process such as press bottle, filling and sealing.

It can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Technical parameter

|

model |

RCGF 14-12-4 |

RCGF 18-18-6 |

RCGF 24-24-8 |

RCGF 32-32-10 |

RCGF 50-50-15 |

RCGF 60-60-15 |

RCGF 70-70-18 |

|

suitable bottle size |

H:170-320mm Dia: 50-100mm volume: 330-2000ml Plastic bottle |

||||||

|

cleaning pressure(Mpa) |

0.25-0.3 |

||||||

|

capacity(b/h) |

2000 |

5000 |

7000 |

9000 |

18000 |

22000 |

25000 |

|

power(KW) |

2.2 |

3.5 |

3.8 |

5.5 |

10 |

13 |

15 |

|

dimension(mm) |

2100×1800 x2700 |

2600×2100 x2700 |

3200×2300 x2700 |

4200×2600 x2700 |

5700×3600 x2700 |

6000×4200 x2700 |

6500×4500 x2700 |

|

weight()KG |

2300 |

3500 |

4600 |

6500 |

10000 |

110000 |

130000 |

Main characters

1) To change bottle shape, the operator only needs to replace the star-wheel, inlet bottle screw and arc guide plate

2) The parts contacting media are made from stainless steel and have no process blind angles to enable easy cleaning

3) Stainless steel bottle clip, the clip does not touch the bottle screw, the rinsing nozzle is “plum blossom” shape, so it can care each inch of the bottle.

4) This machine adopts micro negative pressure hot filling, has high filling accuracy.

5) Screw capping machine designed according to Italy technical, France technology.

6) The cap feeder has the function of protection cap, and also can test no cap status and process cap adding.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for High Quality Manual Filling Machine For Creams - PET bottle juice filling machine – FAYGO , The product will supply to all over the world, such as: US, Cape Town, Gambia, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

Products Recommended

More +-

Factory directly supply Old Pet Bottle Blowing Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

Newly Arrival Pneumatic Piston Filling Machine - Edible Oil Filling Machine – FAYGO

Product introduction This machine is an automatic 2-in-1 monobloc oil filling capping machine. it adopt piston filling type,it could be applicable for all kinds of edible oil, olive oil, sunfl...Learn more -

Factory supplied 20 Litre Water Can Filling Machine - PET bottle juice filling machine – FAYGO

Product introduction This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce PET bottled juice and other non-gas beverage. The CGF Wash-filling-capping 3-in-1unit:Bevera...Learn more -

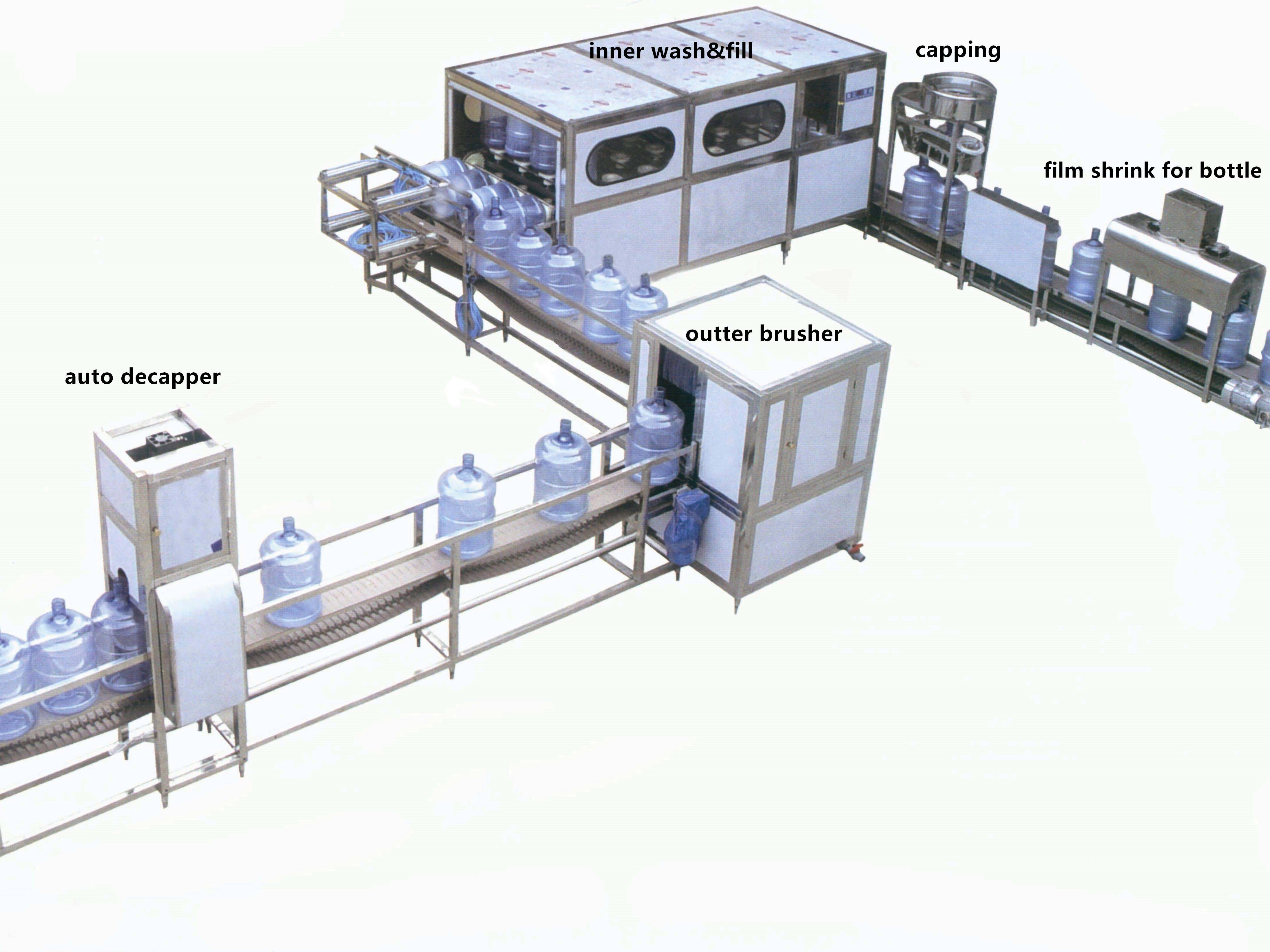

Top Suppliers Manual Bottle Filling Machine Price - 5 Gallon Water Bottle Filling Machine – FAYGO

Description for 5 gallon filling machine This water filling line specially produces gallons bottled dinking water, whose types (b/h) are: 100 type, 200 type, 300 type, 450 type, 600 type, 90...Learn more -

Best Price on Semi Automatic Water Bottle Filling Machine Price - 5L / 10L Rotary Automatic Bottle Filling Machine – FAYGO

Automatic 5L Filling Machine 1. Automatic Bottling 3 in 1 mineral / pure Water Filling Machine adopt Rinsing / Filling / Capping 3-in-1 technology, PLC control, Touch Screen, it is mainly made...Learn more -

Discount Price Global Pet Blowing Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more