Low MOQ for Cpvc Pipe Extrusion Machinery - Pet bottle crushing washing and drying line – FAYGO

Inquiry NowLow MOQ for Cpvc Pipe Extrusion Machinery - Pet bottle crushing washing and drying line – FAYGO Detail:

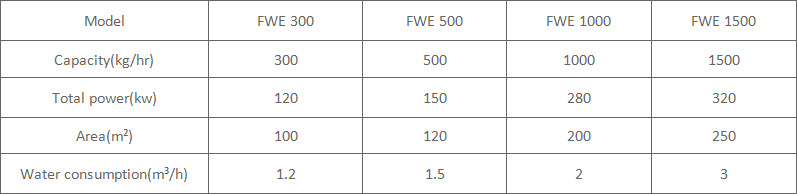

This Pet bottle crushing, washing and drying line transforms waste pet bottles into clean PET flakes. And the flakes can be further processed and re-utilized with high commercial value. The production capacity of our PET Bottle crushing and washing line can be 300kg/h to 3000kg/h. The main purpose of this pet recycling is to get the clean flakes from the dirty even mixture bottles or bottles slice during dealing with the whole washing line. And also get clean PP/PE caps, labels from the bottles etc.

The PET bottle recycling line is consist of the following machines: de-baler, trammel, label remover ,manual sorting table, metal detector, crusher, pre-washer, hot washer, friction washer, float washing tank, dewaterer, drier, zigzag separator, storage hopper and electric control cabinet.

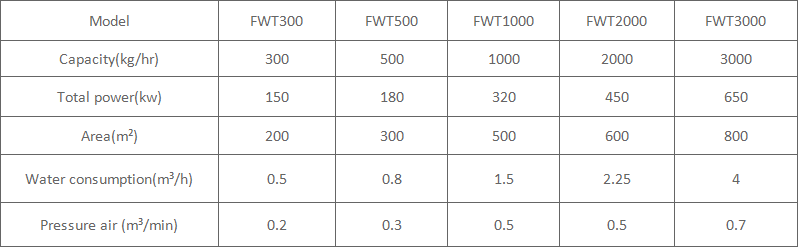

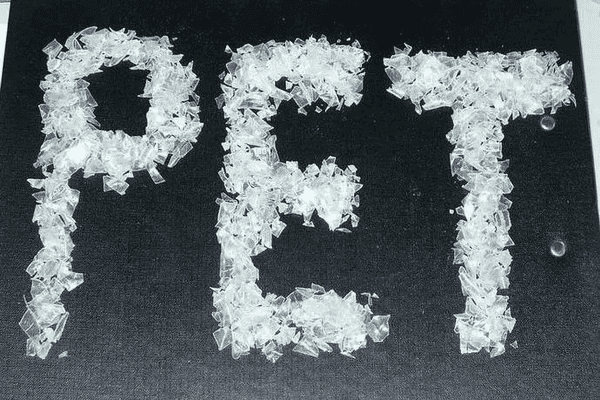

Technical data:

2.PP, PE Crushing, washing and drying line

This PP, PE Crushing, washing and drying line is mainly used to clean the waste plastics, such as PE HDPE LDPE LLDPE PP BOPP Film, bags, bottles, Jerry cans, bucket, basket etc. The waste dirty material will go through crushing, washing, drying, and collecting process, and turn to be clean flakes for pelletizing.

With high efficient crushing,washing and drying, the client can make clean plastic scraps from waste plastics with lowest cost.

The PP, PE recycling line mainly include crusher or shredder machine, friction washer machine, float washing tank, High speed friction washer machine, dewatering machine, hot air dryer system, storage silo etc.

The clean material machine from this washing line can be used to making plastic granules. Our company also supply plastic granulating machine for next process

Technical data:

Product detail pictures:

Related Product Guide:

It is our responsibility to meet your needs and efficiently serve you. Your satisfaction is our best reward. We are looking forward to your visit for joint growth for Low MOQ for Cpvc Pipe Extrusion Machinery - Pet bottle crushing washing and drying line – FAYGO , The product will supply to all over the world, such as: Mecca, Birmingham, Cyprus, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

Products Recommended

More +-

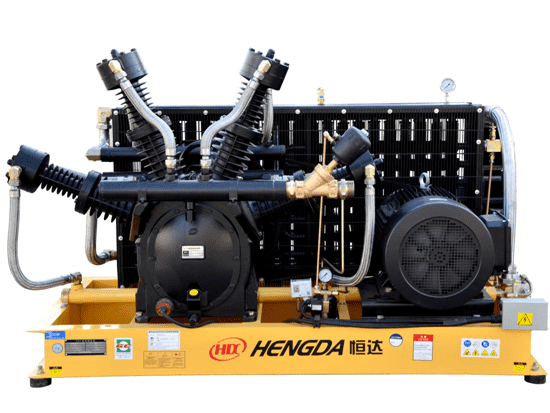

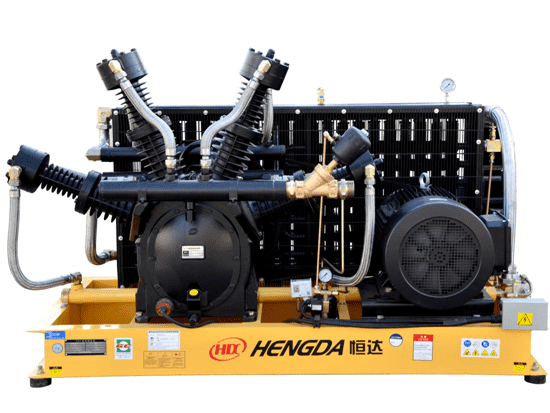

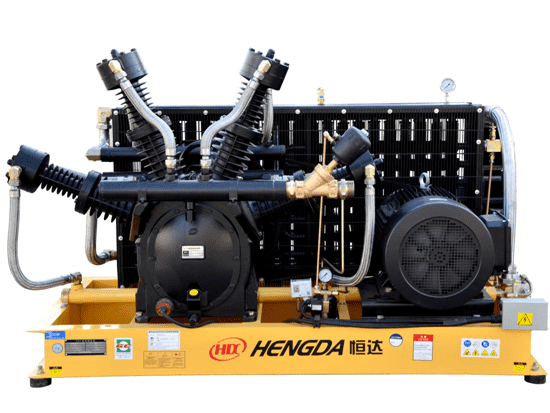

Hot Selling for Double Acting Piston Compressor - Booster compressor – FAYGO

Learn more -

8 Year Exporter Plastic Bottle Maker Machine Price - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

Good User Reputation for Screw Air Compressor Price - Booster compressor – FAYGO

Learn more -

100% Original Factory Free Piston Compressor - Booster compressor – FAYGO

Learn more -

Manufacturer for Screw Drive Compressor - Booster compressor – FAYGO

Learn more -

China Manufacturer for Twin Screw Extruder - Plastic recycling pelletizing line – FAYGO

HDPE pipe extrusion line This line is mainly used to make granules from waste plastic material, such as PP, PE, PS, ABS, PA flakes, PP/PE films scraps. For different material, this pelletizing line...Learn more