Manufacturing Companies for 4 Nozzle Juice Packing Machine - Drinking Water Filling Machine – FAYGO

Inquiry NowManufacturing Companies for 4 Nozzle Juice Packing Machine - Drinking Water Filling Machine – FAYGO Detail:

Drinking Water Filling Machine

This Automatic CGF Wash-filling-capping 3-in-1 Water Filling Machine is used to produce bottled mineral water, purified water, alcoholic beverage and other non-gas Liquid.

This Machine can be applied to all kinds of plastic machine such as PET, PE. Bottles size can vary from 200ml-2000ml meanwhile few changeover is needed.

This model of filling machine is designed for the low/middle capacity and small factory. It takes low buying cost, low water and electricity consumption and few space occupation into consideration at the beginning.

At the same time it can perfectly complete the function of washing, filling and capping. It improves the sanitary conditions and simplifies the maintenance compared with the last generation water filling machine.

Technical parameter

| Model | CGF

14125 |

CGF

16-16-6 |

CGF

24246 |

CGF

32328 |

CGF

404012 |

CGF

505012 |

CGF

606015 |

CGF

808020 |

| Number of washing, filling and capping heads | 14-12-5 | 16-16-6 | 24-24-6 | 32-32-8 | 40-40-10 | 50-50-12 | 60-60-15 | 80-80-20 |

| Production capacity

(600ml) (B/H) |

4000

-5000 |

6000

-7000 |

8000

-12000 |

12000

-15000 |

16000

-20000 |

20000

-24000 |

25000

-30000 |

35000

-40000 |

| suitable bottle specification(mm) | φ=50-110 H=170 volume=330-2250ml | |||||||

| Washing pressure

(kg/cm2 ) |

2~3 | |||||||

| Main Motor power(kw) | 2.2kw | 2.2kw | 3kw | 5.5kw | 7.5kw | 11kw | 15kw | 19kw |

| Overall dimensions

(mm) |

2400

×1650 ×2500 |

2600

×1920 ×2550 |

3100

×2300 ×2800 |

3800

×2800 ×2900 |

4600

×2800 ×2900 |

5450

×3300 ×2900 |

6500

×4500 ×2900 |

76800

×66400 ×2850 |

| Weight (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 | 12800 | 15000 |

Characteristic

1. intelligent contact screen, human design, easy operation.

2. Imported filling valve, avoiding drop leaking, accurate filling quantity.

3. Program logic controller(PLC), easy for changing size or modifying parameters.

4. Pneumatic elements are all imported, stability and reliability.

5. Accurate liquid sensing, automatically adding liquid, ordinary pressure flow passage parameters

6. Solely and specially-designed whole lifting device, easy governing to meet the needs of all kindsof container packing

7. Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

8. Pneumatic executive control valve, high efficiency and safety. Each flow passage can be separately governed and cleaned.

9. Close positioning design, easy governing, suitable for packing of all sizes of bottles.

10. The whole machine is designed according to requirements of buyer’s.

Product detail pictures:

Related Product Guide:

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for Manufacturing Companies for 4 Nozzle Juice Packing Machine - Drinking Water Filling Machine – FAYGO , The product will supply to all over the world, such as: Brisbane, UK, Algeria, Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

Products Recommended

More +-

Competitive Price for Preform Machine Price - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

Manufacturing Companies for 4 Nozzle Juice Packing Machine - 5L / 10L Rotary Automatic Bottle Filling Machine – FAYGO

Automatic 5L Filling Machine 1. Automatic Bottling 3 in 1 mineral / pure Water Filling Machine adopt Rinsing / Filling / Capping 3-in-1 technology, PLC control, Touch Screen, it is mainly made...Learn more -

China Cheap price Blowing Machine - PET Bottle Blowing machine – FAYGO

FG series PET Bottle Blowing machine FG series PET bottle blowing machines fill the gaps in field of domestic high-speed linear blowing machine. Currently, China linear single-mold speed still sta...Learn more -

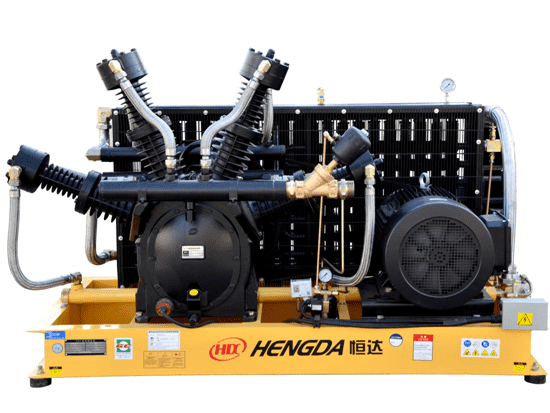

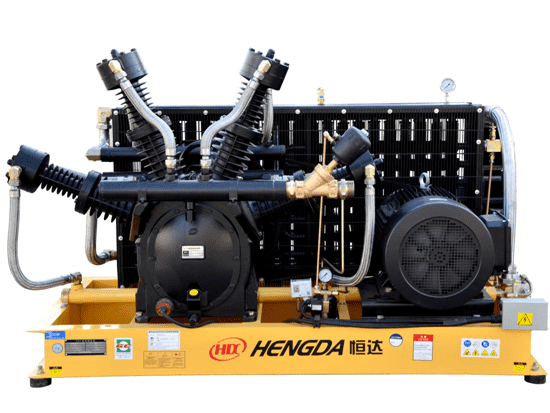

Good User Reputation for Screw Air Compressor Price - Booster compressor – FAYGO

Learn more -

Rapid Delivery for Small Compressor For Air Tools - Booster compressor – FAYGO

Learn more -

PriceList for Pvc Granulation Production Line - PP pipe production line – FAYGO

PP-R/PE-RT pipe extrusion line It is main used for producing PP-R, PE pipes with diameter from 16mm~160mm, PE-RT pipes with diameter from 16~32mm. Equipped with proper downstream equipment, it...Learn more