Manufacturing Companies for Pc Profile Production Line - Single Screw Plastic Extruder Machine – FAYGO

Inquiry NowManufacturing Companies for Pc Profile Production Line - Single Screw Plastic Extruder Machine – FAYGO Detail:

HDPE pipe extrusion line

It is mainly used for extruding thermoplastics, such as PE, PP, PS, PVC, ABS, PC, PET and other plastic material. With relevant downstream equipment (including moud), it can produce various kinds of plastic products, for example plastic pipes, profiles, panel, sheet, plastic granules and so on.

SJ series single screw extruder has advantages of high output, excellent plasticization, low energy consumption, stable running. The gearbox of single screw extruder adopt high torque gear box, which has features of low noisy, high carrying capacity, long service life; the sccrew and barrel adopt 38CrMoAlA material, with nitriding treatment; the motor adopt Siemens standard motor; inverter adopt ABB inverter; temperature controller adopt Omron/RKC; Low pressure electrics adopt Schneider electrics.

By different requirement, SJ series single screw extruder could be designed as PLC touch screen control type extruder and panel control type extruder. The screw could adopt high speed screw to achieve more output.Advantage:

1. world famous brands major parts: SIEMENS motor, ABB/FUJI/LG/OMRON inverters, SIEMENS/Schneider contactors, OMRON/RKC temperature controllers, DELTA/SIEMENS PLC system

2. Experience engineers all with passports ready for customers services.

3. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.

Technical parameter

|

Model |

SJ25 |

SJ45 |

SJ65 |

SJ75 |

SJ90 |

SJ120 | SJ150 |

|

Screw Dia.(mm) |

25 |

45 |

65 |

75 |

90 |

120 | 150 |

|

L/D |

25 |

25-33 |

30-33 |

30-33 |

30-33 |

30-33 | 30-33 |

|

Main Motor(KW) |

1.5 |

15 |

30/37 |

55/75 |

90/110 |

110/132 | 132/160 |

|

Output (KG/H) |

2 |

35-40 |

80-100 |

160-220 |

250-320 |

350-380 | 450-550 |

|

Centre height |

1050 |

1050 |

1050 |

1050 |

1100 |

1100 | 1100 |

|

Net Weight(KG) |

200 |

600 |

1200 |

2500 |

3000 |

4500 | 6200 |

|

L*W*H(m) |

1.2X0.4X1.2 |

2.5X1.1X1.5 |

2.8X1.2X2.3 |

3.5X1.4X2.3 |

3.5X1.5X2.5 |

4.8X1.6X2.6 | 6X1.6X2.8 |

Video

Product detail pictures:

Related Product Guide:

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for Manufacturing Companies for Pc Profile Production Line - Single Screw Plastic Extruder Machine – FAYGO , The product will supply to all over the world, such as: Uzbekistan, Angola, Jamaica, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

Products Recommended

More +-

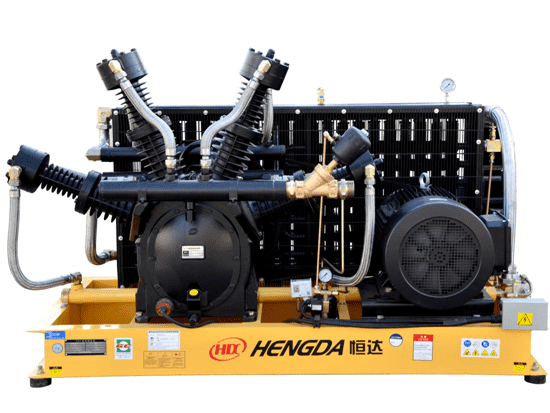

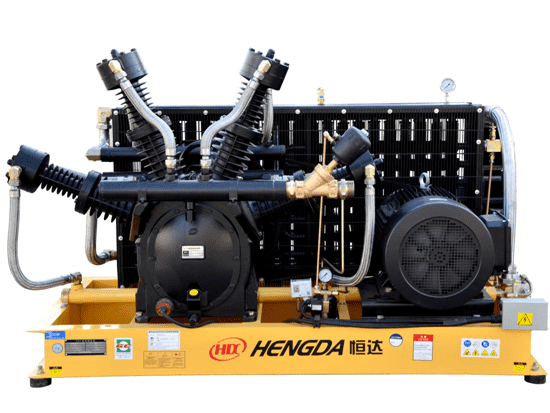

China Gold Supplier for 12v Air Compressor 4×4 - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more -

Special Price for 50 Hp Compressor Price - Booster compressor – FAYGO

Learn more -

Hot-selling 4500 Psi Portable Pcp Compressor - Booster compressor – FAYGO

Learn more -

Factory wholesale Juice Packing Machine - Edible Oil Filling Machine – FAYGO

Product introduction This machine is an automatic 2-in-1 monobloc oil filling capping machine. it adopt piston filling type,it could be applicable for all kinds of edible oil, olive oil, sunfl...Learn more -

Factory making Table Top Liquid Filling Machine Price - Drinking Water Filling Machine – FAYGO

Drinking Water Filling Machine This Automatic CGF Wash-filling-capping 3-in-1 Water Filling Machine is used to produce bottled mineral water, purified water, alcoholic beverage and other non-g...Learn more -

New Fashion Design for Used Rotary Screw Compressor For Sale - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more