PISTON COMPRESSOR

Inquiry NowLow pressure 8-20bar

configuration of our industrial air compressor:

●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to motor below 15HP)

●Each single unit is equipped with air tank when composed of double machine unit. And can be flexibly composed, without purchasing separately and thus save cost.

●With low oil level switch, when the oil level is too low, air compressor will stop running, thus can protech machine.

●Using air cooling system, inter and post cooler, with the characteristic of compact structure, low speed.

●With a 4 micron air intake filter to ensure compressed air clean.

1. Light alloy piston effectively reduces weight and reduces mechanical power consumption。

2.Cast iron cylinder heads, and independent seat enhance the life of the equipment.

3. Equipped with the king of air valve "Herbiger" automatic efficient valve they make the equipment big capacity, more action, high efficiency, long life service.

4. Special design flywheel, V belt drive reduce the operating noise

5. Removable outdoor air intake silencing filter and 10 micron filtration precision effectively improve the quality of the air intake and reduce the inlet temperature.

6.Rotating components adopt two SKF rolling bearings, which ensure the stable operation and greatly reduce the wear and tear of the bearing.

Feature

●cast iron structure: The air cylinder and the crank case use 100% cast iron material, guarantees the unit the service life.

● air cylinder: The deep wing piece type, the independent casting air cylinder may 360 degrees eliminations produce compressed air quantity of heat. Between the air cylinder and the crank case with the bold fastening, is advantageous for the routine maintenance and the maintenance.

●flywheel: The flywheel leaf blade produces one kind “the tornado” the type air current to cool the deep wing piece type air cylinder, the middle chiller and the after cooler.

●intercooler: The finned tube, the immediate packing blows in the flywheel gas place.

●after cooler: The finned tube, the forced-air cooling type, install equally with the middle chiller in the flywheel gas blow place. Compressed air which discharges after the after cooler compared to ambient temperature high approximately about 20℃

●offcenter unloading gear: Release from cold and in air cylinder's air, prevents the unit overload start.

● adjusting device: All high-pressured unit disposes the automatic start/engine off control, moreover may choose the constant speed control and the dual controls.

● self-refrigeration draindown system: The self-refrigeration wash water valve installs on the exhaust separator/valve's support, when the compressor engine off or unloads when the constant speed control mode, discharges the condensed water automatically.

● electrical machinery: TEFC, the IP54 electrical machinery, conforms to the IEC standard.

● actuation: The entire seal shroud “V” the belt transmission, the movement is steady.

● foundation: On the Chungking Steel Works structure's foundation opens has the groove, the electrical machinery may move, is advantageous for the fastening “V” the leather belt.

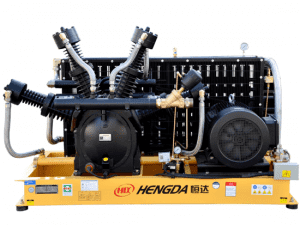

Medium pressure 30-40bar

Components

1、 Light alloy piston effectively reduces weight and reduces mechanical power consumption

2、 Cast iron cylinder heads, and independent seat enhance the life of the equipment.

3、 Equipped with the king of air valve "Herbiger" automatic efficient valve they make the equipment big capacity, more action, high efficiency, long life service.

4、 Special design flywheel, V belt drive reduce the operating noise

5、 Removable outdoor air intake silencing filter and 10 micron filtration precision effectively improve the quality of the air intake and reduce the inlet temperature.

6、 Rotating components adopt two SKF rolling bearings, which ensure the stable operation and greatly reduce the wear and tear of the bearing.

7、 The main wear parts service life

piston ring 6000hours (according to the working environment)

valve plate 6000hours (according to the working environment)

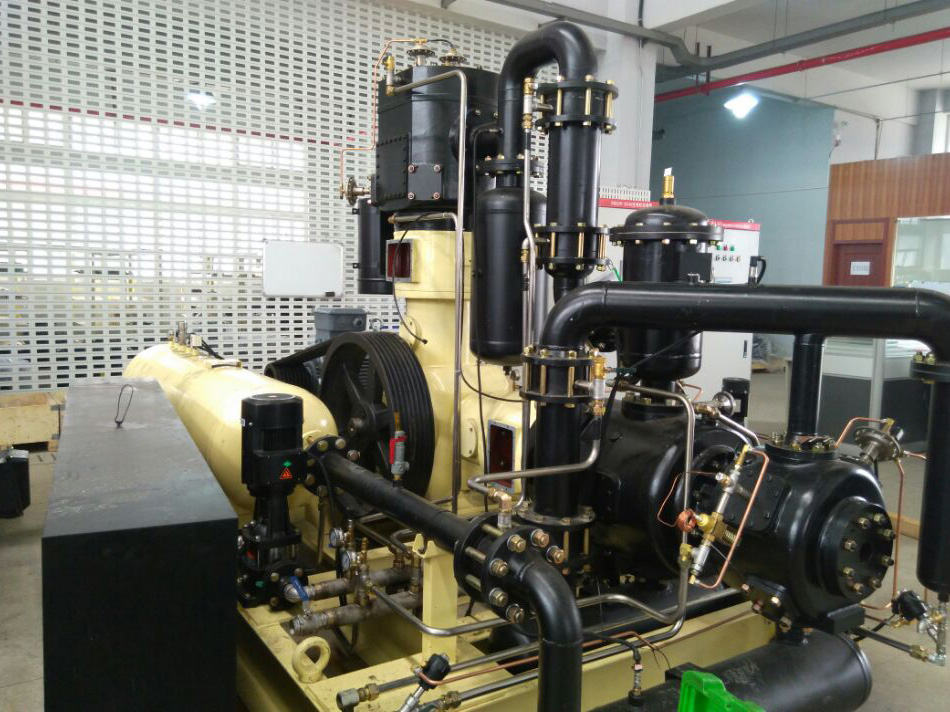

3.Oil free big flow high pressure air compressor(Air flow More than 8.5m3/min)

Oil pool-------Oil filter---Oil pump--Crankshaft-Rod connecting-cross part----Oil pool

Compressor lubrication system adopt pressure lubrication, including external gear pump with a spindle device

Products Recommended

More +-

Booster compressor

Unite decorated air intake system can minimize noise and air temperature and improve the compressor gas production and parts of life.

The “Herbiger” big caliber unloading valve centralizes control intake air and improves the reliability of the compressor control, avoiding the problems of multiple valves.

3 stage compression can make full use of the advantage in balance, cooling and each stage unloading of the W type machine. 3 stage compression can make the pressure reach as high as 5.5 MPa. When the working pressure is 4.0 MPa pressure, the machine is at light load operation, which dramatically increases the reliability

Special design oil scrapper ring can reduce the wear to cylinder, which makes fuel consumption ≤ 0.6 g/h

Learn more -

RZ6600-8600-9600-12000CXE

Gasoline generator set RZ6600CX-E

No matter when and where, our company’s high-quality power output and unique noise reduction technology ensure that the noise at a distance of 7 meters during unit operation is only 51 decibels; Double layer noise reduction technology, separated intake and exhaust duct design, effectively avoids air turbulence, making the air

Learn more -

SCREW COMPRESSSOR

Full-automatically load and unload control the input air full automatically. Compressor will start automatically when there is no pressure, and will stop working when the pressure is full in air tank. When the compressor is short of electricity, the electricity will be in reverse. When the pressure is too high, the temperature is also high, which can protect itself full-automatically. You can use our compressor without any workers on duty.

Learn more -

8000LE

As an emergency power supply, the open rack diesel generator set can quickly solve the problem of power failure for you. It is the best helper for outdoor work, power generation, and welding. High conversion rate of product features, all copper motor, F-class insulation, and high conversion efficiency. Stable output intelligent voltage regulation AVR, stable voltage, and small voltage waveform distortion. Number of digital panels.

Learn more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur