Special Design for Pipe Extruder - Single Wall Corrugated Pipe Making Machine – FAYGO

Inquiry NowSpecial Design for Pipe Extruder - Single Wall Corrugated Pipe Making Machine – FAYGO Detail:

Detailed Product Description

|

Application: |

Produce Single-wall Corrugated Pipes |

Rare Material: |

PP,PE,PA And PVC Granules |

|

Extruder Type: |

Single Screw Extruder |

Pipe Diameter: |

4mm~100mm |

|

Max Speed: |

18m/min |

Motor: |

Siemens-Beide |

|

Inverter: |

ABB |

Control System: |

PLC And Panel Control |

00mm PP PE PA single wall corrugated pipe production line, corrugated pipe making machine

This line is mainly used to produce various single wall corrugated pipes with diameter from 6mm ~ 200mm. It can apply to PVC, PP, PE, PVC, PA, EVA material. The complete line includes:loader, Single screw extruder, die, corrugated forming machine, coiler. For PVC powder material, we will suggest conic twin screw extruder for the production.

This line adopt energy efficient single screw extruder; the forming machine has gears run modules and templates to realize excellent cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall. The main electrics of this line adopt world famous brand, such as Siemens, ABB, Omron/RKC, Schneider etc.

With diferent plastic material, it can make produce different kind of corrugated pipes.

The Process flow of this corrugated pipe line as blow:

Raw material (PP/PE/PA/PVC granule) → Plastic extruder → Mould→ Forming machine →Winder → Finished product

The single wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility. They are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine.

Technical parameter

| Extruder model | SJ30 | SJ45 | SJ65 | SJ65 | SJ75 |

| Motor power | 4kw | 11kw | 18.5kw | 37kw | 55 |

| Pipe diameter | 4~10mm | 10~25mm | 16~50mm | 50~110mm | 50~200mm |

| Production speed | 5~10m/min | 4~12m/min | 2~16m/min | 0.5~8m/min | 0.5~8m/min |

| Output | 8kg | 20kg | 50kg | 80kg | 0.5~8m/min |

Product detail pictures:

Related Product Guide:

With our leading technology as well as our spirit of innovation,mutual cooperation, benefits and development, we will build a prosperous future together with your esteemed company for Special Design for Pipe Extruder - Single Wall Corrugated Pipe Making Machine – FAYGO , The product will supply to all over the world, such as: Congo, Oman, Sri Lanka, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Products Recommended

More +-

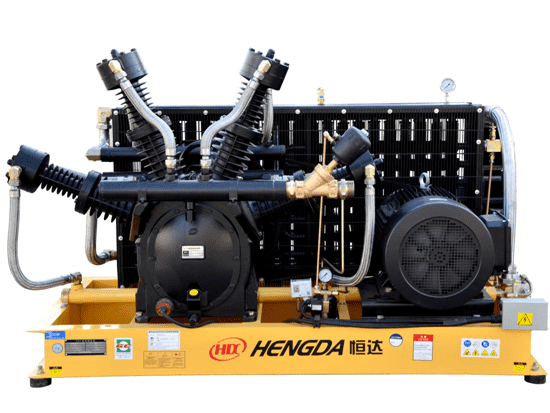

Cheapest Price Truck Mounted Rotary Screw Air Compressor - PISTON COMPRESSOR – FAYGO

Low pressure 8-20bar configuration of our industrial air compressor: ●The standard mode is air adjustment mode, also can be electric adjustment mode according to the customer(only apply to mot...Learn more -

Factory directly Pprc Pipe Machine - Plastic recycling pelletizing line – FAYGO

HDPE pipe extrusion line This line is mainly used to make granules from waste plastic material, such as PP, PE, PS, ABS, PA flakes, PP/PE films scraps. For different material, this pelletizing line...Learn more -

Factory wholesale Portable Compressor For Painting - Booster compressor – FAYGO

Learn more -

Fixed Competitive Price Drinking Water Filling Machine - 5L / 10L Rotary Automatic Bottle Filling Machine – FAYGO

Automatic 5L Filling Machine 1. Automatic Bottling 3 in 1 mineral / pure Water Filling Machine adopt Rinsing / Filling / Capping 3-in-1 technology, PLC control, Touch Screen, it is mainly made...Learn more -

Factory supplied Best Liquid Filling Machine - Edible Oil Filling Machine – FAYGO

Product introduction This machine is an automatic 2-in-1 monobloc oil filling capping machine. it adopt piston filling type,it could be applicable for all kinds of edible oil, olive oil, sunfl...Learn more -

100% Original Plastic Bottle Chips Recycling Machine - HDPE pipe extrusion line – FAYGO

HDPE pipe extrusion line It is widely used in producing HDPE water supply pipes, gas supply pipes. It can make HDPE pipes with diameter from 16mm to 800mm. With many years of plastic machinery deve...Learn more